Embedded insights for development

Measure what matters. Inside the laminate. In real time.

No more assumptions or endless testings. We provide you with interlaminar strain data throughout the development and qualification of your composite structures — increasing speed to market and lowering development costs.

1

Sensor Embedding

2

Sensor Connection

3

Data Aquisition

4

Data Analysis

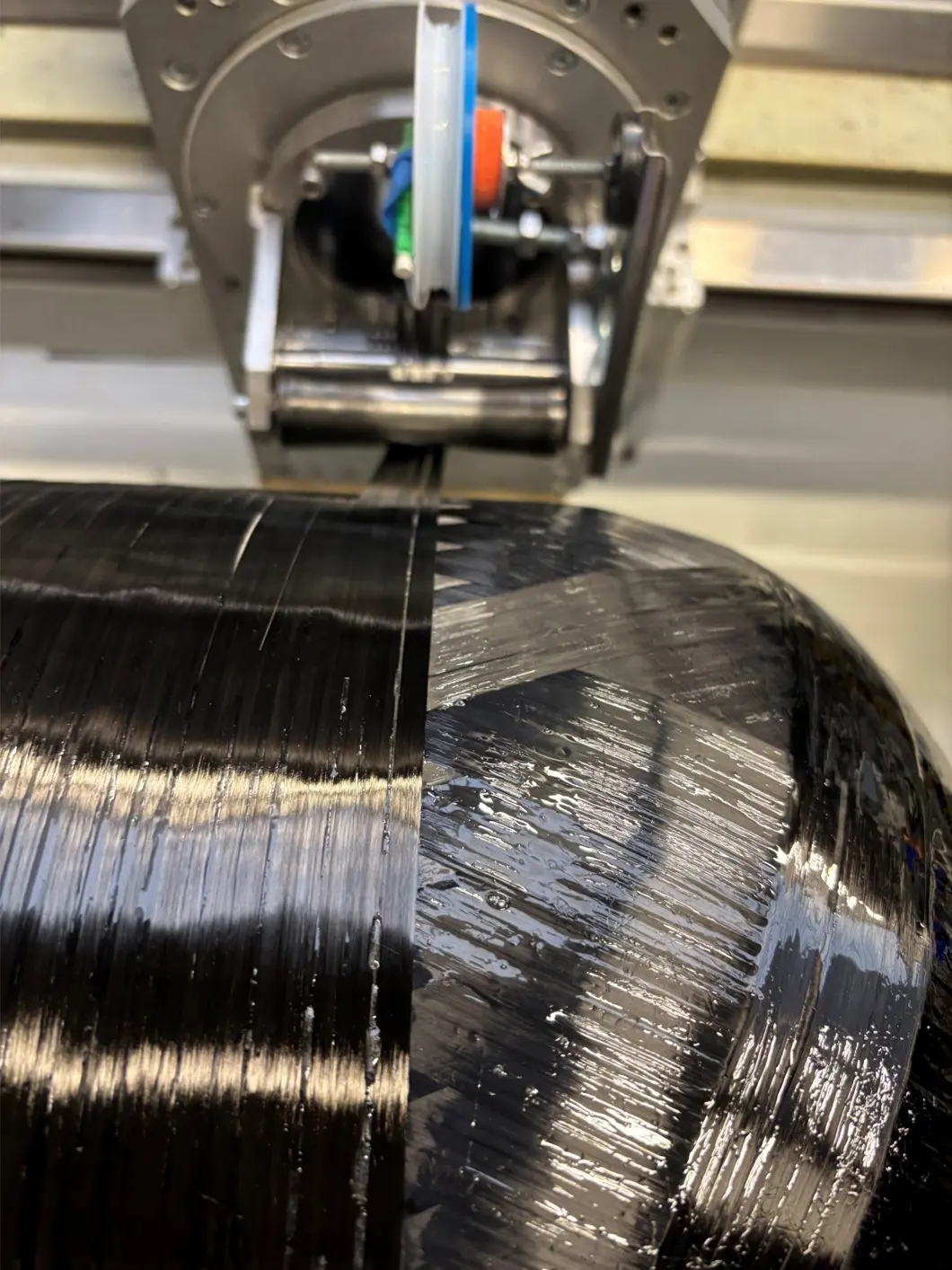

Co Winding /Placement

Adapt these three columns to fit your design need. To duplicate, delete or move columns, select the column and use the top icons to perform your action.

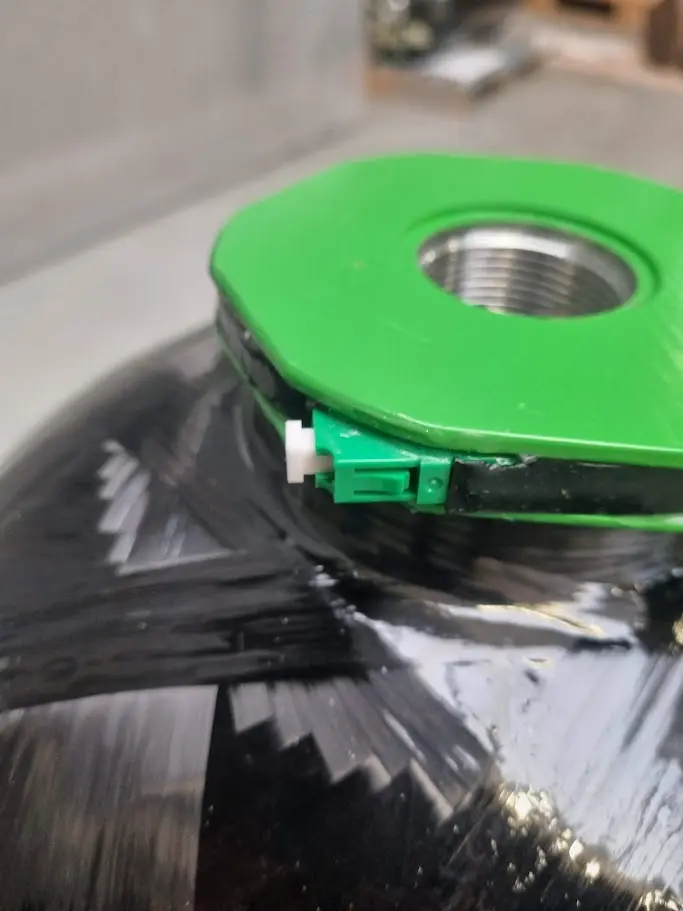

In Process connection

We design robust, test-ready connectors to protect and simplify access to the embedded sensors during handling and testing.

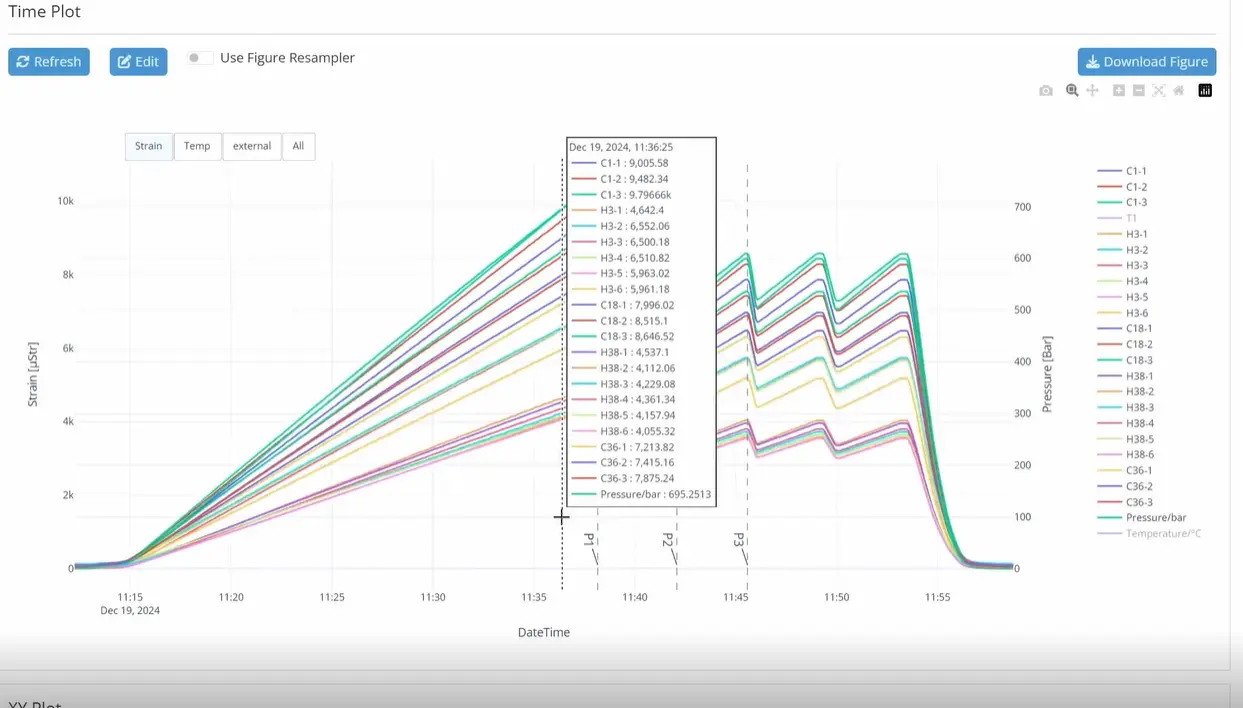

In Process measurement

Track structural behaviour during winding, curing, or testing to validate simulations and detect issues early.

Insights with CS Vision

Visualize, analyze, and report sensor data across all development phases — from prototyping to qualification.

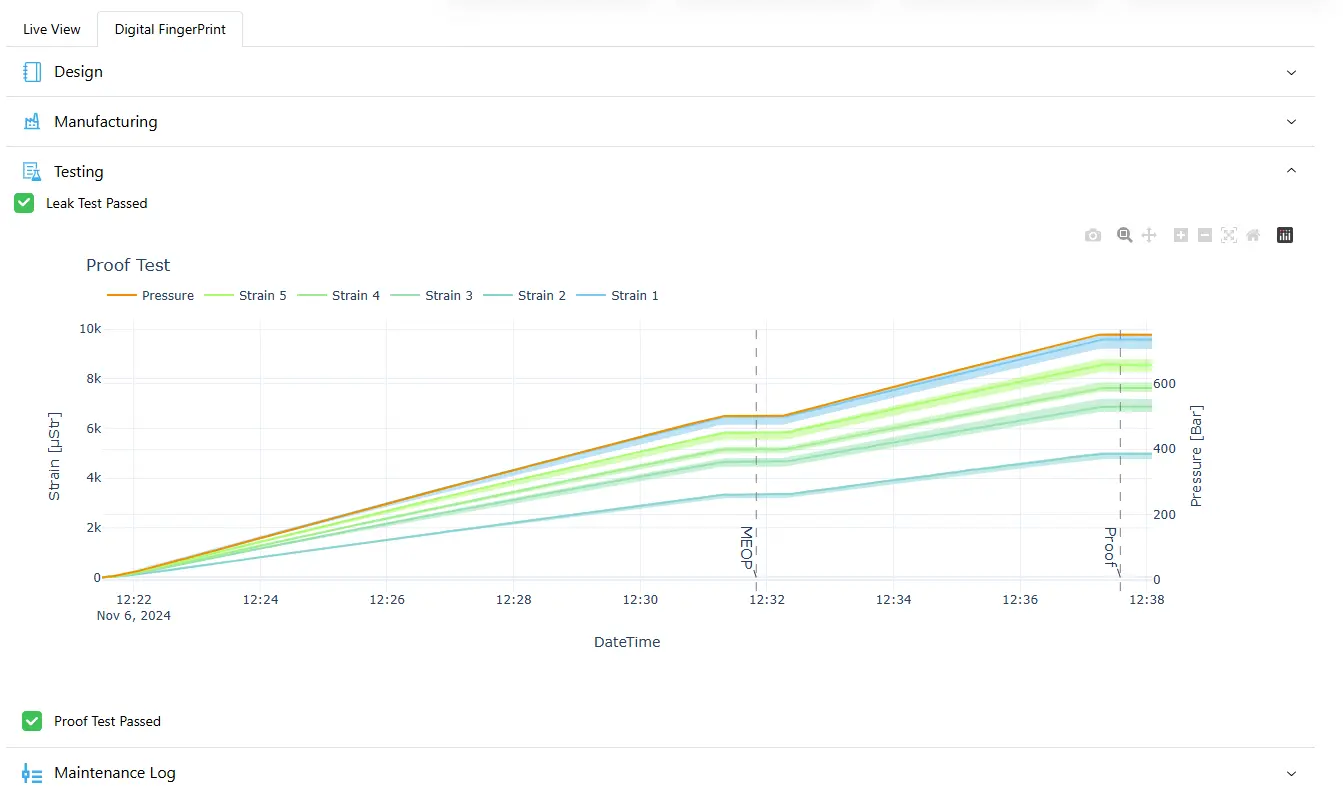

Digital Fingerprint

Every structure starts with a digital identity.

By embedding a standardized fiber during production, manufacturers can capture a unique structural fingerprint of each composite part.

This low-cost, high-impact step creates a digital baseline for every unit — enabling digital fingerprinting, full traceability, condition monitoring, and predictive maintenance throughout its lifecycle.

1

Serial sensor integration

2

Factory Fingerprint

3

Digital Passport.

Embed once. Unlock data for a lifetime.

A single optical fiber, embedded during manufacturing, transforms your composite part into a smart, traceable asset.

With our cost-effective sensor layout and automation-ready solutions, this step integrates seamlessly into your process and adds minimal cost, while unlocking massive downstream value.

Turn your proof or acceptance test into a structural baseline.

By recording the structural behavior during proof testing and/or acceptance testings, we create a digital fingerprint — a "zero state" — unique to each unit. This reference enables future comparisons, anomaly detection, and performance tracking over time.

From tank to cloud — enable smart asset management.

Each fingerprinted tank becomes compatible with CS Predict, allowing operators to monitor degradation, track usage, and extend lifetime — without relying on periodic inspections. This opens the door to predictive maintenance, reduced costs, and safer operations.

Our latest content

Check out what's new in our company !